Installation requirements

The Orbital Shower is the world’s first recirculating shower, pioneering water and energy conservation in both residential and commercial settings. To ensure the system operates as intended and delivers maximum savings, please adhere to the following installation requirements. These are crucial for the proper installation and functioning of the shower system.

If you have any questions or need further clarification on the installation requirements, feel free to contact us at Orbital.

Notice

If you are planning an installation in the United States, please refer to the installation requirements provided here.

The Orbital Shower is designed for both residential and commercial use in fixed environments. It is not compatible with mobile installations. The shower system must be installed in a stable location with a reliable connection to electricity, as it needs to remain powered at all times, even when not in use. To ensure reliable operation and prevent freezing, the system should not be installed in environments where the temperature may drop below 4°C.

Approved installation locations:

Residential homes

Hotels

Gyms

Dressing rooms

Tiny houses etc

Not approved installation locations:

RV's

Trailers

Boats etc

Environment

The Core must be installed in a warm, temperature-controlled environment. The operating ambient temperature should be maintained between 15°C and 35°C. When not in use, the temperature must not drop below 4°C.

Positioning

Distance from Drain: Maximum 3 meters from the drain center to the unit.

Vertical positioning: Can be installed as high as below the head shower and as low as 10 cm from the floor.

Accessibility

The shower core must be installed in a location that allows easy access for routine maintenance and servicing. Ensure there is sufficient space around the unit for technicians to work without obstruction.

Pipe routing

Distance from Drain: Maximum 3 meters from the drain center to the unit.

Vertical positioning: Can be installed as high as below the head shower and as low as 10 cm from the floor.

Incoming Cold Water Temperature: 4-25°C

Incoming Hot Water Temperature: 50-65°C

Maximum Working Pressure Tap Water: PN10

Incoming Water Pressure: 2-10 bar *

Water Supply Flow: 9 liters/minute per inlet hot & cold **

Water Hardness: 3°dH-14°dH , or 53-250mg CaCO₃/liters

Water Iron Content: <0.3 mg/liter

Residual Circuit Breaker: One breaker per Shower Core

Power Supply: One Phase, 230VAC / 50-60 Hz / 16A *

Mains Supply Wire: Minimum 2.5 mm² (rated for 16 A circuit)

|

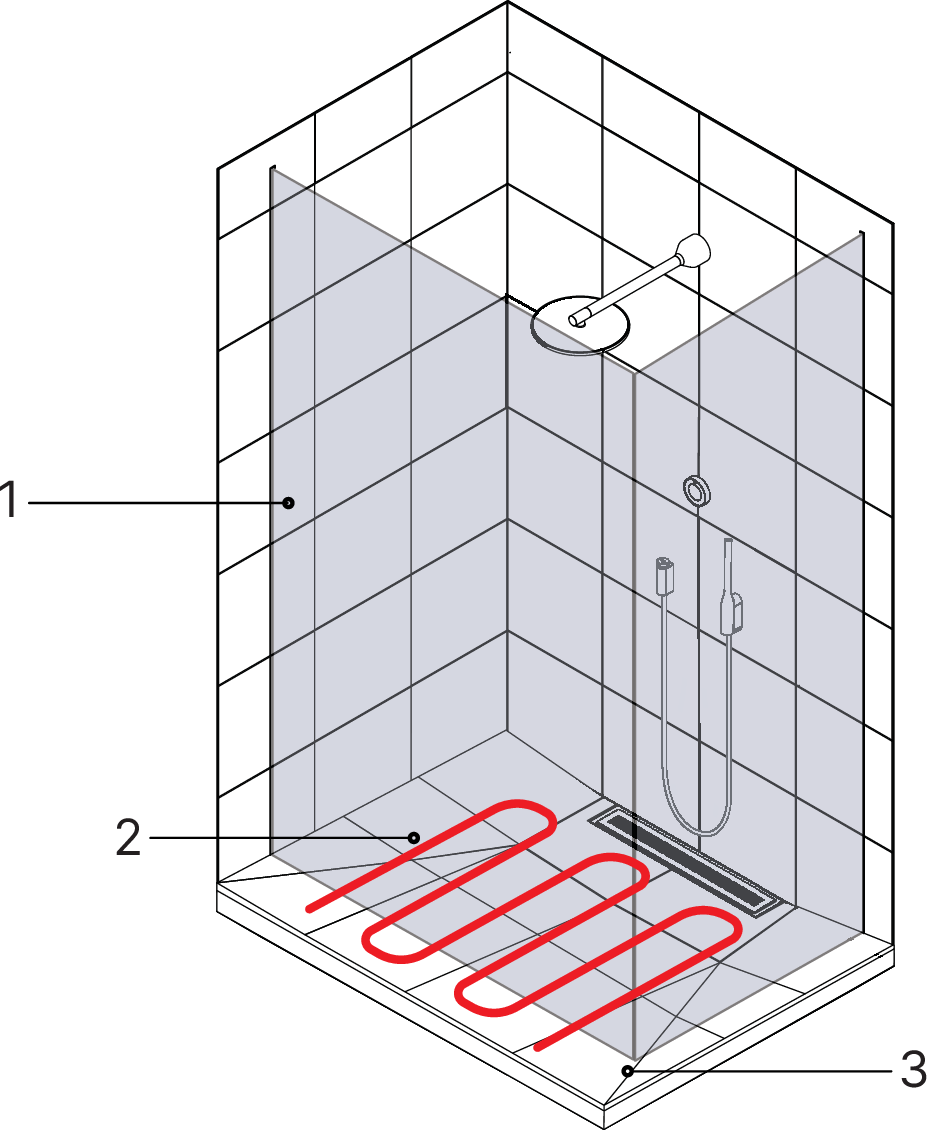

A fully enclosed shower area

By creating a closed shower zone, heat losses are significantly minimized. It is essential to ensure that shower walls and doors go all the way down to the floor.

Underfloor heating

Underfloor heating in the shower area helps reduce water cooling. We recommend placing the underfloor heating as close to the floor fixture as possible.

Floor inclination

A proper inclination is crucial to ensuring the water flows efficiently toward the drain. We recommend creating a slope of 20 millimeter per meter.

Standard Installation: Our standard tiling frame is designed for tiles with a maximum thickness of 10 mm on both the floor and walls. *

Special Order Option: For installations requiring thicker floor tiles, we offer a specially designed tiling frame that supports tiles up to 20 mm on the floor. **

Certain installations may present challenges, such as insufficient power supply, low water pressure, or elevated water hardness. To ensure optimal functionality and user satisfaction, we provide tailored solutions to address these issues:

Power Supply Challenges: For installations with limited electrical capacity, Orbital Systems offers load balancing technology to evenly distribute electrical loads, preventing overloads and ensuring reliable operation.

Low water pressure: In situations where water pressure is insufficient, we recommend the installation of a reciprocating pump to effectively boost pressure, maintaining the system’s performance standards

Water hardness: For areas with high water hardness, we suggest integrating a water softener to minimize mineral buildup and enhance the efficiency and longevity of the system.

These solutions are designed to adapt to a variety of conditions, ensuring that every installation delivers the full benefits of the Orbital Shower system. Our team is ready to assist in identifying and implementing the most suitable options for your specific needs. Please contact support@orbital-systems.com